- Flooring in dairies needs to provide a number of hygienic and operational properties

- The Flowfresh range of polyurethane flooring is ideal for a dairy’s demanding milking and processing areas

- Choose HACCP International certified flooring to ensure that the system is up to the challenge

Modern dairies are not the laid back, slow-moving places that people like to imagine. Instead they are highly productive, fine-tuned facilities that require a considered approach to the design, maintenance and functionality of each and every site involved in the production, processing, storage and transportation of dairy goods.

Being able to manufacture such large quantities of high quality dairy goods relies on a well-oiled infrastructure where performance is taken seriously from the ground up. To create a contemporary, state-of-the-art dairy, it’s particularly important to ensure that the floor underfoot is able to cope with the challenges of this busy, complex sector.

Productivity and cleanability go hand-in-hand, as a site that sacrifices hygiene for higher volumes will risk not only failing to comply with regulations, but it could result in produce becoming contaminated. This is especially true of the floor, as if it is cracked, tarnished or difficult then the site could become compromised.

The Reason for Resin

For this reason, many dairy producers are turning to resin flooring solutions such as Flowcrete’s Flowfresh range thanks to the hygienic properties that these coatings can provide. Seamless and impervious, resin systems are easy to clean and thanks to the resistance this type of flooring has to impacts, chemicals and traffic, it can maintain a fully functional finish for an extended period of time.

Getting the floor right is more than just an operational practicality, as it is also vital to making sure that a dairy complies with the European Union’s food hygiene standards. This is illustrated in EC regulation 853/2004 which stipulates that food business operators must have “hard floors and smooth walls that are easy to clean and disinfect”.

Additionally, EC 854/2004 states that producers “shall put in place, implement and maintain a permanent procedure or procedures based on the HACCP principles”. The floor is central to this, as the regulation goes on to say that “floor surfaces are to be maintained in a sound condition and be easy to clean and, where necessary, to disinfect. This will require the use of impervious, non-absorbent, washable and non-toxic materials”.

The Flowfresh range has been certified by HACCP International thanks to its ability to provide all the properties required for an effective HACCP food safety program within even the largest and most intensive food factories.

Flowcrete has designed its floors to go above and beyond even the strict standards of the European Union, as every Flowfresh system incorporates the antibacterial agent Polygiene®. This additive actively inhibits the growth of bacteria in contact with the floor, a property which has been tested to the ISO 22916 standard.

Making the Floor Do More

It’s not just making sure the floor can stay clean that needs to be considered to make sure that it’s optimised for the task at hand. For example, it’s important to get the size and quantity of aggregate incorporated within the polyurethane mix of a Flowfresh floor correct in order to achieve the right level of slip resistance.

Being able to tailor the floor’s texture is ideal for many dairy spaces, such as the milking parlours, where spilled milk, water from wash downs, mud from boots and effluence from the cattle can all be present. For the safety of the staff and animals moving through the area, they need to be able to grip the potentially wet and slick surface underfoot.

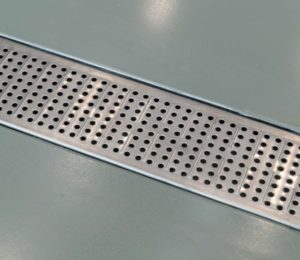

Incorporating stainless steel drainage, run-off channels and coving into the floor coating is also essential here, as it means that once the milking is done the whole area can be easily washed down to remove all contaminants and slippery substances.

However, the frequent and intensive cleaning regimes required within dairy facilities can pose a threat to the floor, as steam cleaning and harsh chemicals will quickly deteriorate an insufficiently robust coating. Flowfresh is able to shrug off thermal shock such as steam cleaning at 120°C and corrosive chemicals, ensuring that the floor won’t corrode or break apart after a deep-cleaning session.

From extremely hot temperatures at one end to freezing conditions at the other, Flowfresh has also been applied in many cold storage rooms and exposed barns thanks to its ability to survive in sub-zero conditions.

In addition to all of these challenges, the sheer physical demands of dairy operations can take a toll on the floor. Point loading from heavy equipment, traffic from staff, cows and forklift trucks, impacts from dropped items and pressure from fully loaded pallets can all chip away at the finish. Flowfresh has been formulated to create a layer with a high cross-linked density, which makes it exceptionally tough. When applied in a thick 6-9mm coating, it can take on all of the above issues every day of the year for an extended period of time.

From the Parlour to the Production Line

Away from the actual milking area are a variety of processing, storage, office, logistics and production spaces, which will likely require all of the above properties to a greater or lesser extent. The versatility of resin floors means that they can be easily tailored to all the different environments and types of facilities found across the dairy industry.

This was recently exemplified at one of the most high-tech dairies in the world, Australia’s Bannister Downs Dairy. When the high-tech facility built a new creamery, 2,350 m2 of Flowfresh SR was used to ensure that it would have a clean, safe and on-brand floor finish for the long term.

If you would like to find out more about specifying the right floor for each part of a dairy complex, get in touch with Flowcrete UK’s expert team today.