DON’T BE FLOORED BY CHALLENGING DESIGN CONSIDERATIONS IN FOOD AND BEVERAGE INDUSTRY

Flooring in food and beverage environments must be slip-resistant, easy to clean, durable and hygienic. These factors pose significant challenges to flooring designs; not only do most floors have to be purpose-built, they must be functional, meeting the strict criteria stipulated above. So what kinds of design considerations need to be made to ensure floors meet hygiene standards at the point of specification?

Keeping it clean

Floor finish is a key design consideration which should fulfill a variety of standards in the European Food Safety Directive. In food preparation areas, flooring must be seamless and easy to clean to meet hygiene levels, particularly as the spread of bacteria must be prevented in food environments at all times. Flooring must also be rinsed thoroughly to remove wash-down residues and any viruses, bacteria or pests that might be present. The finish should also be compatible with certain solvents, including cleaning agents, for the quality of the finish to remain uncompromised.

A finish needs to be impermeable and made to a high specification otherwise employee and consumer safety could be put at risk. An excellent finish, often best provided by dense resin-rich systems, will prevent flaking, cracking and discolouration, making sure a floor looks professional and performs to its best.

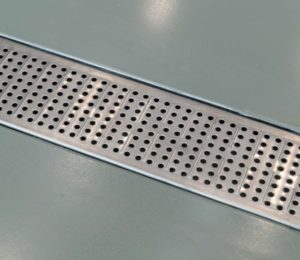

Drainage must be placed in correct areas and never under processing equipment as it obstructs important cleaning procedures. With the assistance of gravity, gradients ranging between 1:100 and 1:80 can be useful for moving any liquids towards drains. Efficient drainage systems are fundamental design considerations as they guarantee cleanliness is maintained at an optimum standard in food environments.

Slip-resistance

Floor finishes must also be slip-resistant. Slips and trips are the most common causes of injury at work, accounting for an average 33% of total work injuries. Injuries tend to occur most often in areas where meat, fruit, vegetable, fat and other residues are present. To counteract this, companies can choose flooring that has an optimum combination of grip and wash-ability to keep employees safe and the facility supremely clean.

The most common method of providing grip to new flooring is to apply aggregate onto the top of the wet surface before it hardens. Aggregate varies in size and type and can create numerous profiles. The most common types are silica, quartz, flint, and aluminium oxide.

Durable designs

Flooring in food environments must be able to withstand high-impact shock and abrasions, whether from large mechanical shocks or a drop of a heavy knife. In the food sector, floors will be put under a significant amount of stress given the nature of the environment, therefore cleanliness, durability and safety are complete priorities.

Flooring solutions must also be compatible with cleaning agents to ensure longevity. Floors with low chemical resistance not only wear down faster, they also create traps for bacteria and viruses can hide. Be mindful of the volume of volatile organic compounds (VOCs) emitted by various floor, wall, ceiling, and other finishes. Flooring products with low VOC emission means air is kept clean, resulting in safer food production and a healthier working environment for employees.

Finding the right flooring system which fulfills a variety of challenging design aspects is difficult, especially in relation to the food industry. With countless years of experience, Sikafloor® systems are created and installed to meet all of these challenging requirements thanks to their flexible design possibilities. From floor finish to drainage system, to durability, Sikafloor® has companies covered.

Credits

Our latest news

For the latest news on FeRFA, its members and the industry.