Food Processing Preparation Areas

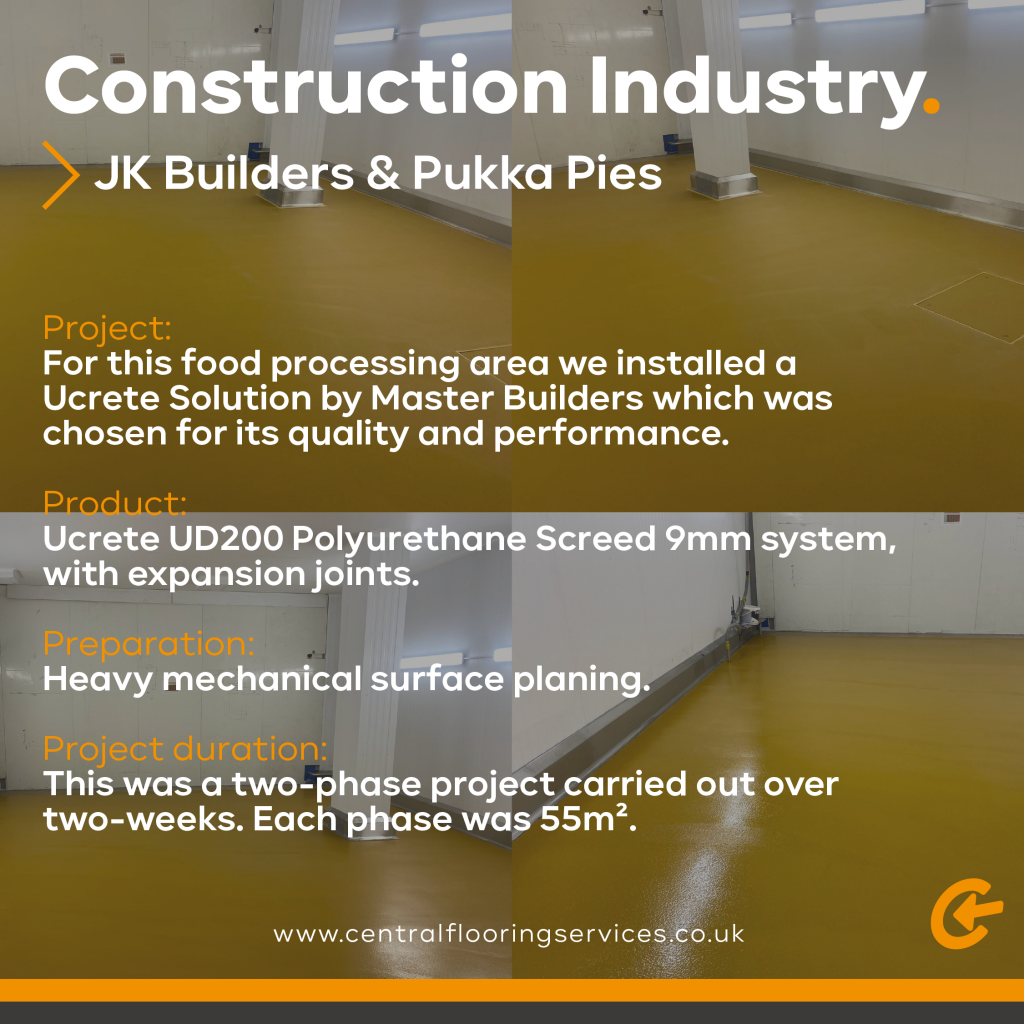

Central Flooring Services have done a fair few projects with J K Builders based in Leicester, including this project for their client, Pukka Pies, the Leicestershire legendary pie maker – especially their signature Steak and Kidney pie, found in pubs, fish and chip shops, and locals.

CFS are one of JK Builders trusted suppliers. For this project they fitted out Pukka’s new food processing preparation rooms with white wall panelling and the CFS team applied the new resin finish.

Project:

For this food processing area we installed a Ucrete Solution by Master Builders which was chosen for its quality and performance.

Product:

Ucrete UD200 Polyurethane Screed 9mm system, with expansion joints.

Preparation:

Heavy mechanical surface planing.

Project Duration:

This was a two-phase project carried out over two-weeks. Each phase was 55m².

About the project

This was a very challenging project because it was in the original building which was more than 50-years old, so many floor levels had to be made up to get to a point where the floors were levelled to an acceptable standard.

As the food processing area was also in the heart of the factory, logistically the installation was trickier to carry out as it’s in use 24/7. CFS team took extra care with the whole project to be absolutely sure that none of the food products were at risk from contamination.

Benefits of Master Builders Ucrete Solution

For the food and drink industry, Ucrete is the ‘Rolls Royce’ standard. It’s exceptionally hard-wearing and super hygienic, making it the perfect solution for this environment. It has resistance to high temperatures, impact, slips, static, strong acids and alkalis, fats, oils and solvents. Even during application Ucrete is non-tainting and completely safe for food handling areas – in fact, it’s HACCP Certified (Hazard Analysis Critical Control Point).

Once installed, this Ucrete flooring solution is in for the long haul.

www.centralflooringservices.co.uk

Credits

Our latest news

For the latest news on FeRFA, its members and the industry.