Reprotec complete large extension for Unipres, Sunderland

Reprotec provided a hard-wearing flooring solution to a 5175 sqm extension (which had formerly been an external concrete storage area) for Nissan car manufacturer Unipres.

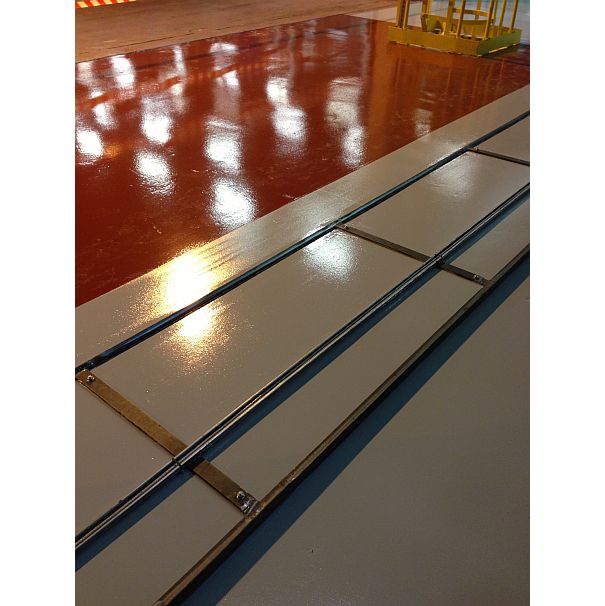

The challenge for Reprotec was to provide a suitable resin system to accept very heavy weights from standing press dies, steel rolls and industrial traffic used in the manufacture of Nissan car parts in what was formally an external storage area. The proposed extension encompassed an area that was not designed for internal use and had no damp proof membrane. The implications of removing 2070 cubic tonnes of old concrete to landfill and relaying new could not be considered so a solution had to be found that would be breathable and not cause problems in the future. The project was undertaken during one of the harshest of North East winters which required the construction of an external tent. The client wanted a smooth finish not the heavy brush surface profile of the existing concrete, which has to diamond ground and vacuum blasted. Test samples were carried out and the Remmers BS3000 SG system was chosen because of its tough, durable finish and its exceptional breathability to allow any moisture that could be trapped in the concrete to escape without causing damage to the resin finish. The early arrival of the presses, taking over much of floor area, meant that the project has to be completed in nine separate sections over 14 months while production was carrying on in surrounding sections.

Credits

Our latest news

For the latest news on FeRFA, its members and the industry.